About Us

Honda Motorcycle & Scooter India

Honda Motorcycle & Scooter India Pvt. Ltd. (HMSI) is the wholly-owned subsidiary of Honda Motor Company, Japan – the World’s No.1 two-wheeler company. Commencing its Indian 2Wheeler operations in May 2001, Honda in the last two decades has grown to become India’s 2nd largest two-wheeler company with over 55 millionhappy customers.

Product Portfolio

Red Wing (BSVI scooter & motorcycle models)

| Category | Segment | Engine | Models |

|---|---|---|---|

| Manufacturing | ATSC | 110cc |

Dio 110

|

|

Activa

|

|||

| 125cc |

Activa 125

|

||

|

GRAZIA 125

|

|||

| MC | 110cc |

CD 110 Dream

|

|

|

Livo

|

|||

| 125cc |

SP 125

|

||

|

Shine 125

|

|||

| 160cc |

Unicorn

|

||

|

X-Blade

|

|||

| 180-200cc |

Hornet 2.0

|

||

|

CB200X

|

BigWing (exclusive premium motorcycle business)

| Category | Segment | Engine | Models |

|---|---|---|---|

| Manufacturing | Fun Bikes | 300cc |

CB300R

|

|

CB300F

|

|||

| 350cc |

H’ness CB350

|

||

|

CB350 RS

|

|||

| CKD/CBU | 500cc |

CB500X

|

|

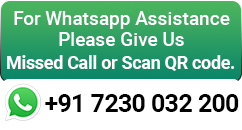

| 650cc |

CBR650R

|

||

|

CB650R

|

|||

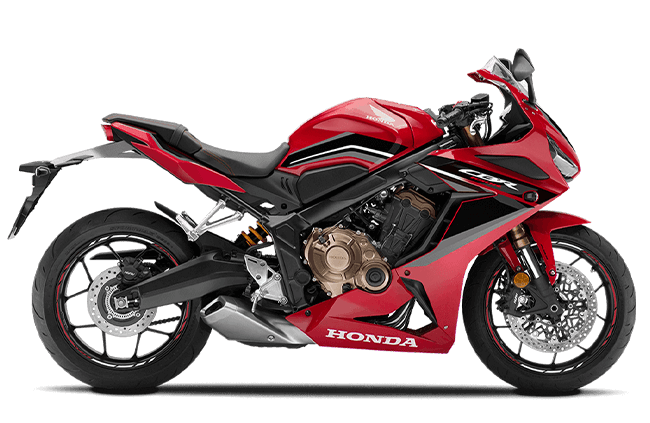

| 1000cc |

CBR1000RR-R Fireblade

|

||

|

CBR1000RR-R Fireblade SP

|

|||

| 1100cc |

Africa Twin Adventure Sports

|

||

| 1800cc |

Goldwing Tour

|

Network Expansion

Red Wing

-

Honda caters to millions of customers across both urban and rural India through its extensive sales and service network of over 6000 touchpoints.

-

Providing additional support are Honda’s 280+ Best Deal outlets (in over 200 cities) which offer one-stop solution for buying, selling & exchanging pre-owned Honda 2Wheelers.

BigWing (exclusive premium motorcycle business vertical)

Reaching closer to its premium biking fans, the differentiated Silver Wings expanded from its first Gurgaon showroom inaugurated in ending of FY’20 to now over 100 BigWing touchpoints across both BigWing Topline (for entire premium motorcycle range from 300cc to 1800cc) and BigWing (exclusively for mid-size motorcycle segment) retail formats throughout the country.

Production factories

-

Honda started production in 2001 from its 1st plant in Manesar, Haryana.

-

In 2011, Honda expanded to 2nd plant in Tapukara in District Alwar (Rajasthan).

-

Reaching closer to its customers, Honda inaugurated its 3rd plant in Narsapura in the southern state of Karnataka and its 4th plant in Vithalapur (Gujarat)

Corporate Social Responsibility

-

Honda India Foundation has devoted all efforts in supporting the fight against COVID-19 pandemic.

-

Honda swiftly diverted resources to protect the community at large like sanitization equipment to COVID Warriors, ambulances for medical emergencies and food packets for the underprivileged during the pandemic

-

Honda has inaugurated Skill Enhancement Centers across 20 states, taking the total count to 51.

-

Honda India Foundation in association with Government of Haryana inaugurated its first Institute of Driving Training and Research (IDTR) in Karnal.

Road Safety

-

Road Safety is one of the cornerstones in Honda’s vision for Indian 2Wheeler landscape. In the last 20 years, Honda has provided safety education & training to more than 48 lac individuals under its three pillars.

-

While, Honda’s 10 Traffic Training Parks (TTP) conduct educational programs for kids & adults, 7 Safety Driving Education Centers (SDEC) give training to learner license applicants & traffic rule violators.

-

Settling in the new Normal, Honda launched its digital road safety initiative ‘Honda Road Safety E-Gurukul’ in May’20. Since then, Honda has digitally sensitized over 8 lac Indians.

Honda Motorsports: Conquering the Speed

-

Identifying young talent to train them into next-generation riders, we are now in our next phase of chalking a clear growth path for our riders from an early age. Introducing ‘IDEMITSU Honda India Talent Hunt’ in 2018, Honda presented a platform for developing iconic Indian racers for National & international Championships.

-

Taking Indian motorsport to global standards, Honda is now the FIRST two-wheeler manufacturer in India to introduce its legacy moto3 machine NSF250R in Indian domestic racing.

-

Besides, we are building the next generation of young riders for competing at global podiums like Thailand Talent Cup and Asia Talent Cup as the first steppingstone.

-

In 2020, Honda globally marked yet another milestone as the 1st motorcycle manufacturer to achieve 800 Grand Prix victories.

-

2021 Dakar Rally saw Honda’s factory team Monster Energy Honda Team triumph with the first 1-2 victory since 1987 fueled by riders Kevin Benavides and Ricky Brabec finish 1st and 2nd.

Awards

In its journey of 20 years, Honda Motorcycle & Scooter India (HMSI) has won more than 200 prestigious awards. In 2022, Honda continued for its new products, committed efforts towards environment conservation and manufacturing excellence.

Manufacturing Excellence: Honda Motorcycle & Scooter India (HMSI) received the Best two-wheeler OEM by FADA, GreenCo Platinum Plus rated automobile company in India to Narsapura Plant (Karnataka), HMSI’s Manesar Plant Bagged Award by HAREDA for State Level Energy Conservation Competition.

Product Excellence: Honda Motorcycle & Scooter India (HMSI) product lineup also continued to add glorious feathers to its hat.Honda CB350RS – Two-wheeler of the year (upto 400cc) by TopGear Awards 2022. Consistently replicating stellar success, Honda CB500X - Adventure Bike upto 600cc, Honda CB650R - Reader’s Choice – Bike of the Year, Honda CB500X and CB200X – Premium Bike of the Year & Entry Level Bike of Year respectively at this year’s Bike India Awards (2022). During the last year, H’ness CB350 was awarded as Two-wheeler of the year, H’ness CB350 Bike of the year (upto 350cc) and Hornet 2.0 Bike of the Year (upto 200cc) by Bike India Awards (2021). Honda H’ness CB350 also bagged the Zee News Motorcycle of the Year while CB500X won the Mid weight bike of the year – Jagran Hi-Tech Awards.

In-House Facilities

Pressure Die Casting

Pressure die casting process used to produce critical shape parts with minimum machining, to optimize cost and productivity.

Machining

Energy efficient Collaborative Robots (COBOT) are installed for pick and place application .

Press Shop

Energy efficient press shop, to draw the metallic sheet into desired shape.

Welding

Grinding Robot for 0B Line Finishing, 6 axis moves in Angular & Straight direction.

Painting

High efficient reciprocator used for painting of parts.

Engine Assembly

Engine assembly facility equipped with latest technologies like Traceability, DC Tools, Vision system & advance part supply system.

Frame Assembly

Vehicle assembly through advance technology, lean work flow with good shop floor appearance.

Vehicle Inspection

Quality guarantee of 100% vehicles through dynometer inspection.